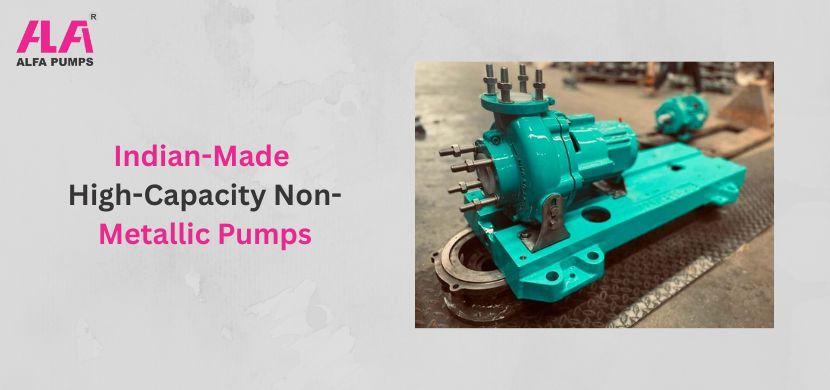

A non metallic chemical pump is a pump made from special plastics instead of metals. These plastics, also called polymers, can handle very strong and dangerous liquids. When industries work with acids, alkalis or solvents, normal metal pumps quickly rust and fail. This is where non metallic corrosion resistant pumps are critical. They are designed for pumps for corrosive chemicals, making sure liquid moves safely without damaging the pump. With options like PP, PVDF Chemical Pump and PFA-Lined Pumps, companies get better safety, longer life and less breakdowns. These pumps protect people, machines and the environment.

Understanding Non-Metallic Pumps:

A non metallic chemical pump is different from a normal metal pump. The material used fights rust and chemical attack. These pumps are often made of polypropylene (PP), PVDF, PTFE or PFA.

Such materials provide excellent corrosion resistance. And long service life in tough chemical process conditions. Unlike metal, which reacts with acids or salts, polymer pumps stay safe. This makes them ideal as pumps for corrosive chemicals.

- PP, PVDF Chemical Pump is commonly used for mild to medium chemicals

- FA, PTFE Lined Pumps are used for very aggressive chemicals.

- These pumps are lightweight, easy to maintain and very reliable.

- They ensure smooth chemical transfer, good efficiency and safe operation.

A non metallic corrosion resistant pump is trusted where performance, compatibility and safety matter most.

Industry Uses of Corrosion Pumps:

Industries depend on non metallic chemical pumps where metals cannot survive. In chemical plants, they transfer acids and alkalis. In pharmaceutical units, they handle solvents safely. In water treatment, they pump chlorine and other corrosive liquids. Even food industries use PP, PVDF Chemical Pump for hygiene-based processes.

But there are limits. These pumps cannot handle very high temperature or extreme pressure like some metallic pumps.

For example, PFA, PTFE Lined Pumps can take higher heat than polypropylene. Still they have their limits. Selecting the right pump depends on liquid type, working condition and safety standards.

Choosing the Right Pump Material:

Every chemical is different and pump material must match the liquid. A wrong match can cause leaks, cracks or sudden pump failure. This matching is called compatibility. Without it, even the best non metallic corrosion resistant pump can fail. Correct selection saves cost, improves efficiency and ensures safety. We will now show how pumps for corrosive chemicals are carefully selected.

- Polypropylene (PP) pumps work safely with mild acids and alkalis.

- PVDF is stronger. So it’s used to carry pumps that carry aggressive acids like nitric or sulfuric.

- PFA, PTFE Lined Pumps are best for very strong acids, solvents and toxic liquids.

Performance Factors in Pump Selection:

When buying a non metallic chemical pump, engineers must check:

- Flow rate and head which indicates how much liquid it can move and how high.

- Efficiency means using less energy to pump more.

- Seal types means some liquids need strong seals to stop leaks.

- Temperature and pressure – every polymer has a limit.

For example, PP, PVDF Chemical Pump handles medium duty. On the other hand PFA, PTFE Lined Pumps handle tough duty. Good design and compatible material ensures long life, less maintenance and safe chemical transfer. A wrong design/ material means early breakdowns and safety risks.

Indian Standards and Compliance:

In India, non metallic corrosion resistant pumps must meet certain legalities. You need to match the global standards set by organizations like the ISO, ANSI and ASTM. These ensure correct testing of corrosion resistance, pressure and safety.

- For industries like chemical or pharma, following these standards is not a choice but a legal need.

- PFA, PTFE Lined Pumps and PP, PVDF Chemical Pump must also meet environmental and worker safety norms.

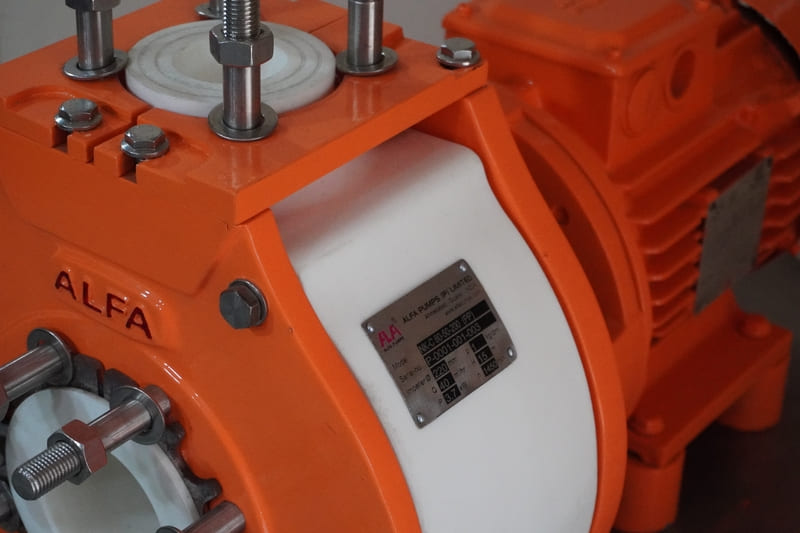

- Trusted vendors like Alfa Pumps give proper certifications.

- Choosing certified pumps for corrosive chemicals reduces risk, keeps plants running smoothly.

- These certifications and following protocols, will also prove your legal compliance during audits or government checks.

Cost vs Lifetime Value of Non-Metallic Chemical Pump vs Others:

| FEATURE | Cheap Local Pump | Non Metallic Chemical Pump (PP, PVDF / PFA, PTFE Lined) |

| Initial Price | Low | Higher |

| Corrosion Resistance | Weak – fails quickly in acids/alkalis | Strong – built for corrosive chemicals |

| Maintenance Needs | Frequent repairs, high downtime | Minimal servicing, long intervals |

| Spare Parts Cost | High over time | Lower due to fewer failures |

| Safety & Compliance | Risk of leaks, non-standard | Certified, safe, meets ISO/ANSI/ASTM |

| Pump Life | 1–2 years average | 5–10 years average |

| Overall ROI | Poor, hidden losses | High, proven savings over years |

Reliable Maintenance and Service:

Every pump needs care. Common issues in pumps for corrosive chemicals include seal wear, leakage and bearing failure. Preventive checks reduce such risks. Cleaning and correct startup also increase pump life. Excellent vendors like Alfa Pumps who supply PP, PVDF Chemical Pump or PFA, PTFE Lined Pumps always provide spares and service. Without this, downtime increases. A non metallic chemical pump lasts longer when service support is quick. Authenticity depends on design as well as a proper maintenance schedule. Always buy pumps with easy access to spare parts; this ensures smooth operation in chemical process industries.

Vendor Checklist for Buying Non-Metallic Chemical Pumps:

Buyers in chemical, pharma and water industries need confidence that their pumps for corrosive chemicals are tested, safe and backed by service. When choosing a supplier, buyers must look at certain aspects beyond price. This checklist ensures plants stay safe, efficient and compliant.

Alfa Pumps, the most trusted vendor of non metallic corrosion resistant pump always offers

- Strong warranty.

- Proper certifications (ISO, ANSI, ASTM).

- Testing reports for corrosion resistance.

- Spare parts and quick service.

- Trustworthy supply chain.

- Companies selling PP, PVDF Chemical Pump or PFA, PTFE Lined Pumps must prove long-term support.

Call us now to know more,

Don’t risk your people, plant or profits on weak pumps. Select only proven non metallic chemical pumps that deliver safety, durability and compliance. Act now – every day with the wrong pump costs money and risks safety. Get expert advice, certified solutions and reliable service today.

FAQs:

These pumps are specially made to handle acids, alkalis, and solvents without getting damaged. They help industries safely move hazardous liquids where metals fail, making them a trusted choice for corrosion-safe polymer process pumps for chemical transfer.

Polymer pumps do not rust or react with harsh liquids, so they last longer and work smoothly. Because of their chemical resistance, many factories prefer plastic corrosion-handling pumps for industrial chemicals over metal alternatives.

These pumps are used in chemical plants, water treatment, pharma and even food processing. Their safe, clean operation makes them suitable as acid-alkali resistant industrial transfer pumps for daily fluid handling.

Flow rate, temperature limit, head and seal design must be checked before installation. These factors help you get the best chemical-resistant polymer transfer pumping solution for your process.

No, they usually require less maintenance because polymers don’t corrode or react with chemicals. With routine inspections of seals and bearings, low-maintenance corrosion-resistant pumping equipment can run efficiently for long periods.

Their starting price may be slightly higher, but they offer longer service life and low repair costs. Over the years, these long-life corrosion-handling industrial pump solutions provide higher savings than cheap alternatives.

Mr. Sanket Patel is a visionary industrial leader and managing director of Alfa Pumps. He leads the company’s innovation in fluid handling solutions, focusing on chemical process pumps designed for corrosive fluids.