India’s mining sector contributes nearly 2.5 percent to national GDP and supports steel, power, cement and infrastructure growth. Behind this scale lies a hidden workhorse: mining slurry pumps. When mines fail to move ore, tailings, or process waste smoothly, losses multiply fast. Reliable pumping decides uptime, safety and cost control. Across Indian iron ore, coal and copper belts, pump performance now directly impacts profitability and global competitiveness.

Why Mining Slurry Pumps Performance Matters More Than Ever in India:

Indian mining conditions are among the toughest in the world. High solids concentration, sharp ore particles, long pipeline distances and extreme weather all put constant pressure on pumping systems. Mines today cannot afford frequent pump breakdowns or unstable slurry flow. Every hour of downtime affects production targets, power usage, manpower planning and delivery commitments.

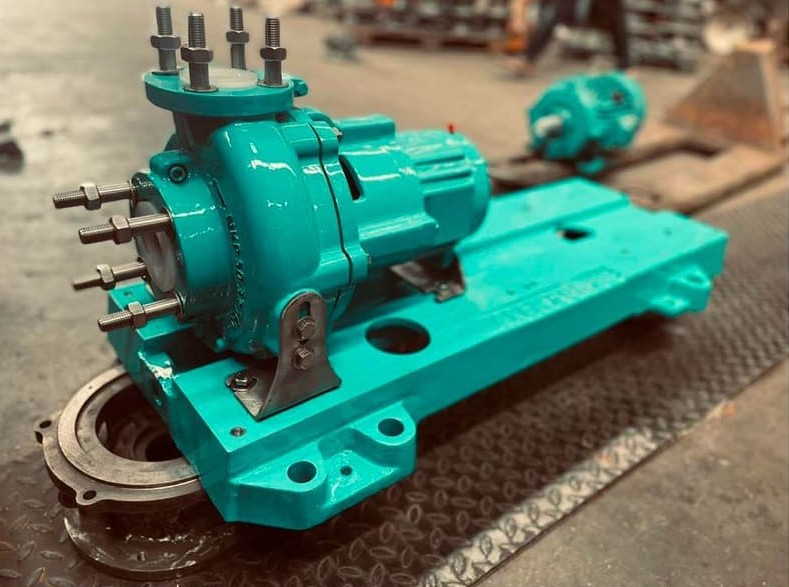

Heavy-duty pump ranges like the high-flow structural slurry pumps are increasingly selected for such harsh duties, where continuous operation and structural strength are critical.

Mining companies are now realising that slurry pumps are not just supporting equipment. They are core production assets. Selecting the right pump directly impacts output stability, operating cost and long-term mine economics.

India’s Mining Growth is Forcing Pump Upgrades:

India produced over 900 million tonnes of coal plus more than 250 million tonnes of iron ore annually. This is the data according to the Ministry of Mines. New auctions and capacity expansions are pushing mines deeper and farther from processing plants. Longer pipelines, higher solids concentration and tighter timelines mean outdated pumps fail faster. This scale is why mines are shifting toward engineered slurry solutions instead of standard equipment.

As mines expand, slurry characteristics also change. Ore hardness increases with depth, particle size distribution varies and slurry density fluctuates. Pumps installed years ago often cannot handle today’s operating conditions. This is forcing mining companies to reassess pump selection and upgrade to heavy-duty slurry pumps designed for present and future needs.

Understanding How Slurry Pumps Work in Mining Operations:

Mining operations usually deal in transporting liquid mixed with sharp, heavy solids via pumps. Ordinary pumps fail here. Slurry pumps for mineral processing are designed to move these mixtures. They do so without clogging or rapid damage. They use centrifugal force to keep solids suspended while maintaining flow. Thick casings, hardened impellers and controlled clearances protect internal parts.

In Indian mines, slurry density can exceed sixty percent solids by weight. This creates constant impact and abrasion. Heavy-duty slurry pumps handle this via wear-resistant alloys and rubber linings. Correct pump speed ensures slurry particles do not sediment inside pipelines. mining equipment pumps also maintain pressure balance across long pipe runs, common in open-cast mines.

Pumps must always be selected based on actual slurry data. This ensures steady output and protects downstream equipment.

Role of Slurry Pumps in Improving Mining Efficiency:

Efficiency in mining means stable production and that too with minimal interruptions. Mining slurry pumps have a significant role here. According to Indian Bureau of Mines data, unplanned stoppages cost mid-size mines several crores annually. Pump failures are a major contributor.

Modern Slurry pumps for mineral processing reduce internal turbulence, lowering energy consumption per tonne moved. In India, where power costs form a large share of operating expenses, this matters. Heavy-duty slurry pumps last longer between overhauls. This reduces the shutdown frequency.

Reliable mining equipment pumps also stabilise grinding and flotation circuits. Consistent slurry flow improves recovery rates and reduces reprocessing losses. Mines that upgrade pumps typically see measurable reductions in maintenance hours and spare inventory. Over time, these gains compound into lower cost per tonne and stronger margins.

The Real Cost of Pump Failure – Industry estimates from Indian open-cast mines show that one hour of slurry system downtime can cost between ₹8–15 lakh, depending on output size. Most losses come from missed production targets and emergency maintenance. Reliable pump systems directly protect daily revenue.

Read Also: Smart Ways to Boost Pump Performance and Control Energy Costs

Key Applications of Slurry Pumps Across the Mining Lifecycle:

Mining is a chain of processes and pumping connects them all. During ore extraction, abrasive slurry handling becomes critical when crushed rock mixes with water. Early-stage transport often contains sharp particles that destroy weak pumps quickly.

In beneficiation plants, mining slurry pumps feed mills, cyclones and flotation cells. Even small flow variations reduce separation efficiency. Slurry pumps for mineral processing ensure uniform feed rates, improving concentrate quality.

Tailings transport is one of the toughest duties. Slurries here are thick, coarse and chemically aggressive. Heavy-duty slurry pumps move tailings over kilometers without segregation or pipeline erosion. In underground mines, backfill systems depend on pumps to safely return waste underground.

Across washing plants and slurry pipelines, mining equipment pumps also support water recovery and reuse, a growing priority in India. Effective Abrasive slurry handling reduces environmental risk. And all this, while keeping operations compliant with tightening regulations.

Safety, Compliance and Environmental Impact of Reliable Mining Slurry Pumps:

Pump reliability is not only about production. It directly affects safety and environmental compliance. Pipeline failures, slurry spills and tailings leaks often start with pump instability. Reliable mining slurry pumps reduce these risks and help mines meet DGMS and environmental norms.

Efficient slurry pumps also support water conservation by enabling recycling and recovery systems. This is especially important in water-stressed mining belts like Rajasthan, Karnataka and Odisha.

Read Also: Non-Metallic Pumps for Corrosive Chemicals A Buyer’s Guide

Common Challenges in Slurry Pump Operations and How They Are Addressed:

Mining sites face wear, misalignment, cavitation and energy waste. Many failures occur because mining slurry pumps are oversized or poorly installed. Excess speed increases erosion. Low suction causes air ingress and vibration.

Advanced Slurry pumps for mineral processing now use modular designs. Wear parts can be replaced quickly, reducing downtime. Improved metallurgy extends service life even under severe abrasive slurry handling conditions.

Modern heavy-duty slurry pumps are engineered to reduce shaft deflection and bearing heavy slurry load. Condition monitoring alerts operators before damage spreads. Experienced mining equipment pumps suppliers also provide correct duty calculations and commissioning support. This combination of design and discipline drastically cuts unexpected breakdowns and maintenance shocks.

Cheap Pumps Cost More Over Time – Many mines still buy pumps based on initial price. Data from Indian maintenance audits shows lifecycle costs can be three times the purchase price due to frequent part replacement and energy waste. Pumps engineered for duty conditions reduce total ownership cost, thereby stabilising the long-term budgets.

Read Also: How Wear and Corrosion Silently Destroy Metal Pumps and Cut Their Lifespan

Future Innovations & Technological Advancements in Mining Slurry Pumps:

The future of pumping is smarter and cleaner. Mining slurry pumps are increasingly fitted with sensors. They track vibration, temperature and even wear & tear. This avoids sudden failures.

New Slurry pumps for mineral processing use advanced composites and optimized hydraulics. These designs reduce power draw while maintaining strength. In India, rising energy costs are driving the demand for pump efficiency improvements. Heavy-duty slurry pumps are also becoming more adaptable. This is allowing mines to handle changing ore characteristics without full replacements.

Next-generation mining equipment pumps focus on longer lifecycle value. Manufacturers investing in innovation will dominate as mines push for automation, safety and lower emissions.

Conclusion: From Indian Mines to Global Standards:

Indian mining is expanding fast, but margins are under pressure. India’s mining conditions are among the toughest—high solids, long runs, extreme wear. Pumps that perform here naturally meet global mining standards. This makes Indian-engineered slurry solutions highly suitable for Africa, Australia and South America, where similar challenges exist. But operations that will delay upgrading Heavy-duty slurry pumps, will lose efficiency every day. Alfa Pumps delivers engineered reliability backed by field experience. Mines that act now secure uptime, savings and long-term stability. Partner with Us to gain back your vigor of new and better competitiveness.

FAQs:

Mining slurry pumps with long-life wear-resistant components prevent unexpected failures and allow continuous operation. Reliable pumps reduce emergency maintenance and help mines achieve stable production with fewer stoppages.

Choosing the right pump based on slurry density and ore characteristics ensures smooth flow and prevents sedimentation inside pipelines. Proper selection protects downstream equipment and optimizes energy consumption in large mining projects.

Efficient slurry transport systems lower the energy used per tonne of material moved. Pumps designed for low-energy slurry movement can save significant operating costs, which is critical in high power-cost regions of India.

Yes, mining equipment pumps are specifically designed for abrasive slurry circulation. They use wear-resistant materials to manage heavy solids and chemicals, keeping mining operations smooth and reducing equipment wear.

Stable slurry flow from pumps ensures consistent mineral separation efficiency in mills, cyclones, and flotation cells. This improves concentrate quality and reduces the need for reprocessing, saving time and cost.

Mr. Sanket Patel is a visionary industrial leader and managing director of Alfa Pumps. He leads the company’s innovation in fluid handling solutions, focusing on chemical process pumps designed for corrosive fluids.