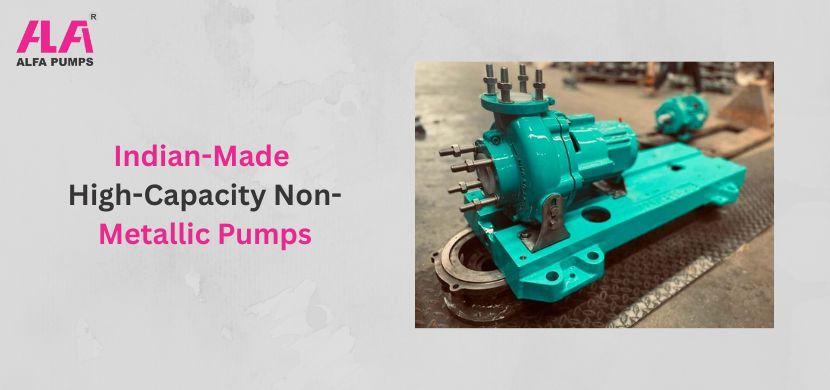

In every chemical, pharmaceutical and water treatment plant, pumps run the heart of the operation. There are two key options metal pumps

(such as stainless steel, cast iron, and even premium grades like titanium alloys) and non-metallic chemical pumps. Buyers mostly look only at the price tag, but that is not enough. Pumps run for years and the real expense is in energy, downtime, repair, corrosion and spare parts.

Didn’t understand this? Check this out: In India alone, corrosion costs across industries top USD 110 billion annually, according to ISSDA. On the other hand, for industrial pumps, this accounts for up to 20–50% of operational energy usage. This showcases how smarter pump choices can drive massive lifecycle cost savings.

The total of all these is called the lifecycle cost or total cost of ownership (TCO). A good pump must give long life, fewer problems and better efficiency. This is why smart managers compare full lifecycle cost, not only purchase price.

Initial Cost vs Lifecycle Cost:

A standard metal pump usually costs less in the beginning compared to advanced non-metallic options. But that is only the upfront cost. The real picture comes when you add maintenance, energy consumption, spare parts and downtime losses. That is the lifecycle cost. Even premium titanium pumps, while offering higher corrosion resistance than ordinary metals, still carry long-term costs when compared to non-metallic alternatives.

Non-metallic pumps may look costlier at purchase, but over time they save money. They are corrosion resistant, need fewer repairs and give better reliability. This lowers the TCO. In many plants, the cost of repairs and energy bills over ten years is many times higher than the first price of the pump.

So, a buyer must ask: “What is the cost over the pump’s full life?” This is where non-metallic vs metal pumps show a clear difference. Looking at only the purchase price can lead to wrong choices. Looking at the full lifecycle cost shows the true ROI and value of non-metallic pumps.

Non-Metallic vs Metal Pumps – Maintenance & Repair Savings:

Chemical and pharma plants often handle acids and harsh liquids. Metal pumps suffer fast corrosion in these conditions. This means repeated repairs, downtime and spare parts. The costs add up quickly.

Non-metallic chemical pumps resist corrosion. They last longer and need fewer part changes. This saves money on both repair bills and labor. For a plant engineer, this also means less stoppages and fewer complaints from the shop floor. Over the years, this difference will bring down the total cost of ownership. It also improves plant reliability. Simply put, less repair means more savings and steady industrial operations.

Non-Metallic vs Metal Pumps – Downtime & Productivity Gains:

When a metal pump fails due to any corrosion or wear and tear, the whole pipeline stops. In a chemical or pharmaceutical plant, this stoppage can be very costly. Delays = wasted batches, missed deadlines and extra labour.

Non-metallic pumps are more reliable because these are corrosion resistant, less wear and tear. They fail less often. This keeps the production running. Even saving a few hours of downtime can prevent big losses. Over a year, the gain is huge. For procurement managers and plant engineers, the main value of a pump is not only the price tag. But how well it supports smooth and continuous industrial operations.

Compliance & Safety-Related Costs:

Pump failures are not just about money. In chemical plants, a leaking metal pump can create chemical spills causing worker injuries and pollution. Such incidents can bring legal action, fines or even plant shutdown.

Non-Metallic Chemical Pumps Reduce This Risk:

- Their corrosion resistance and leak-proof design keep operations safe.

- By choosing these pumps, companies also avoid costs linked to safety penalties and environmental clean-up.

- Compliance with standards becomes easier. This protects both money and company reputation.

- For long-term investment security, a safe and reliable pump is as important as or repair costs.

Vendor Cost Support & Warranty:

The story does not end with buying a pump. Because of higher wear and corrosion, Metal Pumps often need repeated servicing without strong warranty cover. This adds more expense. Support from the vendor also matters. Trustworthy suppliers of non-metallic pumps like Alfa Pumps provide

- Strong warranty

- Easy access to spare parts

- Annual service plans.

In short, our support for non-metallic pumps will reduce downtime, cut future worries and keep costs predictable. For procurement teams, this means better investment and smoother plant life, keeping the full TCO low for years.

Connect with us today to calculate your savings and total TCO

For procurement managers, plant engineers, and operations heads, the smart decision is clear. A pump should not just run today; it should deliver value across its full lifecycle cost. Non-metallic chemical pumps stand out because they cut downtime, lower energy consumption, resist corrosion and reduce repair needs even compared to premium metals like titanium. This means real cost savings and higher ROI year after year. Do not let a low sticker price hide bigger future expenses. Secure efficiency, safety, and reliability in your plant with the right choice.

Switch to non-metallic vs metal pumps for proven, cost-driven industrial operations

Mr. Sanket Patel is a visionary industrial leader and managing director of Alfa Pumps. He leads the company’s innovation in fluid handling solutions, focusing on chemical process pumps designed for corrosive fluids.