In Indian manufacturing, margins are under constant pressure. Power tariffs rise. Downtime costs explode. Yet pumps quietly run in the background, consuming energy every minute. This is where most plants lose money without noticing. Understanding and controlling Pump operational costs is now essential for Indian industries that want stable operations, predictable expenses and sustainable profitability.

High Pump operational costs are rarely caused by one big failure. They come from small inefficiencies repeating every day. Poor hydraulic balance. Wrong operating points. Uncontrolled flow. All of this adds up.

When industries focus on energy efficient pump operation, the impact is immediate. Electricity bills stabilise. Process stability improves. Maintenance teams breathe easier. Plants that achieve lower pump energy consumption gain a long-term edge over competitors still running legacy systems.

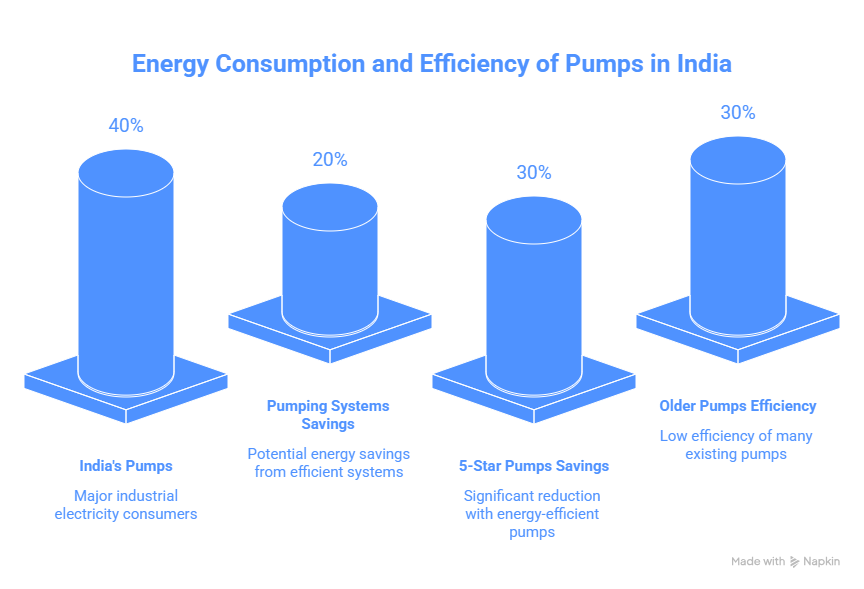

Before we move ahead take a look at these global stats:

- India’s pumps consume ~40 % industrial electricity.

- Pumping systems can save ~20 % energy.

- 21+ million inefficient agricultural pumps exist.

- 5-star energy-efficient pumps cut ~30 % consumption.

- Indian centrifugal pumps dominate ~63 % of the market.

- Industrial pump market ~USD 1.07 billion (2025).

- Many older pumps operate under 30 % efficiency.

Alfa Pumps approaches efficiency as a business tool, not an engineering checkbox. Because real savings show up when decisions reduce pump lifecycle cost, not just capital spend.

How Correct Pump Selection Improves Performance and Lowers Energy Costs:

Most energy losses begin before the pump is installed. Wrong selection locks inefficiency for years.

Oversized pumps increase power consumption in pumps every hour. Operators throttle flow. Motors overwork. Bearings fail early. On the other side, undersized pumps struggle, overheat and collapse under demand.

Correct selection aligns flow, head, fluid behavior and operating hours. This is the foundation of lower energy consumption. Alfa Pumps focuses on actual process data, not catalogue shortcuts.

Accurate selection reduces pump energy usage across all operating conditions. It stabilises pressure, It improves seal life, and It reduces vibration.

Indian industries see immediate Industrial pump cost savings when pumps operate near their design efficiency. Over time, correct selection directly reshapes the lifecycle cost, because fewer breakdowns mean fewer replacements.

This is especially critical in chemical handling, where the right energy-efficient chemical transfer pump prevents energy loss and material damage together.

Read Also: How to Select the Right Chemical Transfer Pump for Your Industry

Optimising Pump System Design to Reduce Pump Operational Costs:

Even the best pump fails inside a bad system.

- Poor suction piping, sharp elbows and undersized lines increase friction losses. This forces pumps to work harder, driving up pump operational costs silently.

- System optimisation focuses on balance. Alfa Pumps evaluates piping geometry, valve placement and control logic to support the pump efficiency instead of resisting it.

- Reduced friction immediately lowers pump energy usage. Motors draw less current. Heat generation drops. Reliability improves.

- For chemical facilities, system redesign helps cut down overall costs in chemical plants where continuous operation amplifies losses. Small hydraulic improvements create long-term Industrial pump cost savings.

- Optimised systems also protect assets. Over time, better design improves pump lifecycle cost by extending service intervals and reducing spare consumption. Efficiency does not come from one component but from system thinking.

Role of Preventive Maintenance in Enhancing Pump Efficiency:

Neglect is expensive…always! Maintenance is about protecting profit.

When pumps operate with worn impellers or misaligned couplings, power consumption in pumps rises gradually. Plants often notice only when failures happen. Preventive maintenance restores efficiency before breakdowns. Alfa Pumps promotes condition-based maintenance that protects pumps throughout the year.

Simple actions = alignment checks, seal inspections, bearing monitoring. These reduce operational costs without stopping production. Clean internals maintain stable pump energy usage.

Plants that follow maintenance discipline achieve consistent lower pump energy consumption even as equipment ages. This directly impacts the lifecycle cost, because assets last longer and failures become predictable. Over time, preventive maintenance delivers real industrial pump cost savings, not theoretical ones.

Improving Pump Energy Efficiency Through Controlled Operation and Demand-Based Flow Management:

Running pumps at fixed speed is outdated thinking. Efficiency today is about intelligence.

If the industrial demand fluctuates, then excellent pumps should respond. Variable speed operation matches output to demand and reduces waste. Flow control through speed optimisation cuts power consumption in pumps dramatically. Alfa Pumps integrates control strategies that maintain the pump operation under changing loads.

Demand-based flow reduces pump energy usage during partial load conditions. Motors run cooler. Mechanical stress drops. Plants that adopt controlled operation achieve measurable lower energy consumption without process compromise. This also stabilises overall operational costs during peak tariff periods.

Over time, controlled operation reshapes pump lifecycle cost by slowing wear. This is where modern Industrial pump cost savings truly come from.

Reducing Chemical Pump Wear Through Proper Material Selection:

In chemical industries, wear equals waste. Wrong materials lead to corrosion, erosion and swelling. This destroys efficiency and spikes Pump operational costs through leaks and frequent shutdowns.

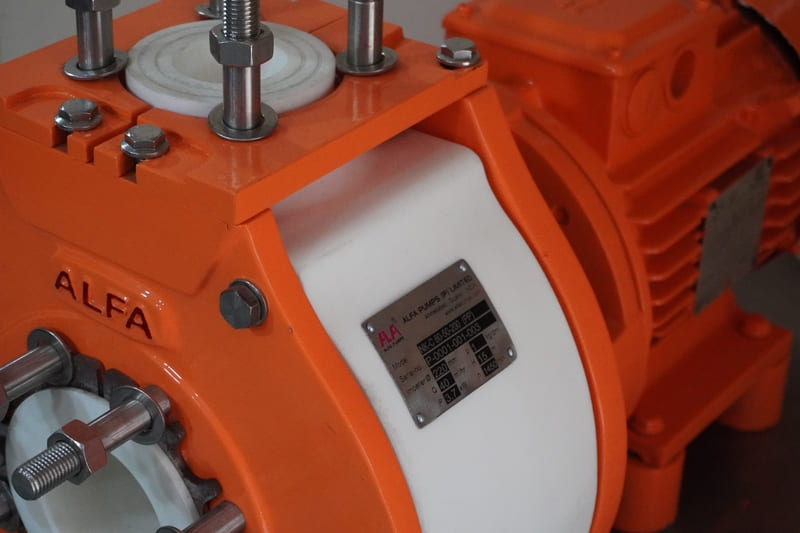

Alfa Pumps selects materials based on actual chemical compatibility, temperature and solids content. The right Energy-efficient chemical transfer pump maintains smooth internal flow and consistent efficiency.

Better materials stabilise pump energy usage over time. Internal clearances remain intact. Performance stays predictable. This approach helps plants cut down pump operational costs in chemical plants where continuous exposure accelerates failure. Proper material selection protects energy efficient pump operation even in aggressive media. Long term, material science decisions define the overall lifecycle cost and unlock sustainable Industrial pump cost savings. Durability is efficiency in slow motion.

Read Also: How Wear and Corrosion Silently Destroy Metal Pumps and Cut Their Lifespan

How Alfa Pumps’ Monitoring & Performance Audits Help Cut Pump Operational Costs:

Efficiency fades without visibility. What gets measured stays efficient.

- Monitoring systems expose rising Power consumption in pumps before damage occurs. We conduct performance audits to identify deviations early.

- Data-driven audits restore Energy efficient pump operation without trial and error. Plants quickly reduce operational costs by correcting real issues.

- Monitoring validates lower pump energy consumption targets and protects improvements over time. Trends reveal hidden losses before failures happen.

- Regular audits also optimise Pump lifecycle cost and secure ongoing Industrial pump cost savings.

Connect Today for Smart Pump Optimisation:

Efficiency is now a competitive weapon. Short-term fixes never deliver long-term savings. Alfa Pumps focuses on strategy, selection and not just design, control and materials. We also provide you regular pump monitoring. Together, these reduce pump operational costs and lock in lower pump energy consumption. Indian industries that invest in smart pump optimisation today will dominate tomorrow. Book a consultation today with us to know more about how we can help you optimise your business operations.

FAQs:

Industrial pumps consume excess power mainly due to wrong pump sizing for industrial applications, throttled flow, and poor system design. When pumps do not operate near their best efficiency point, energy loss increases every hour of operation.

Yes, oversized pumps increase pump energy usage under partial load conditions. Operators are forced to throttle flow, which wastes energy and increases wear on bearings and seals.

Poor piping layout, sharp bends, and undersized pipes increase friction losses. Optimised pump system design for energy efficiency allows smoother flow, reduces motor load, and improves overall pump performance.

Wrong materials cause corrosion and erosion, increasing internal clearances. Correct material selection for chemical transfer pumps maintains smooth flow paths and stable efficiency over long operating hours.

Energy and maintenance form the biggest part of pump expenses. Lower pump lifecycle cost through energy-efficient operation means reduced electricity bills, fewer repairs, and longer equipment life.

Energy and maintenance form the biggest part of pump expenses. Lower pump lifecycle cost through energy-efficient operation means reduced electricity bills, fewer repairs, and longer equipment life.

Mr. Sanket Patel is a visionary industrial leader and managing director of Alfa Pumps. He leads the company’s innovation in fluid handling solutions, focusing on chemical process pumps designed for corrosive fluids.