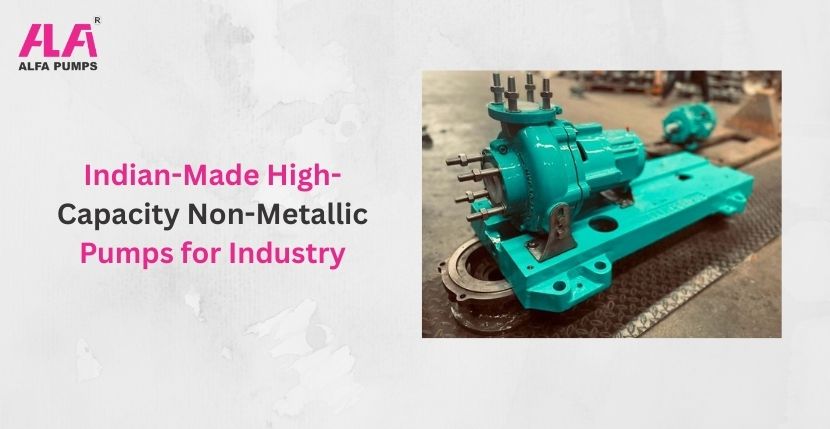

India’s industrial backbone is evolving and pumping solutions must evolve with it. Today’s process industries demand reliability at scale, where high capacity industrial pumps are quite powerful plus intelligent in design. Indian made non-metallic pumps are redefining expectations across industrial applications. Engineered to withstand aggressive chemicals, continuous loads and harsh operating environments? Yes, these heavy duty non metallic pumps deliver long service life without corrosion failures.

More importantly, high capacity non metallic pumps combine volume handling with material integrity. This makes them a smarter alternative to metal pumps across chemicals, water treatment, mining and manufacturing—built for India, proven for the world.

What Are High Capacity Non-Metallic Pumps?

High-capacity pumping is not about size alone. It is about sustained flow, material strength and uptime. High capacity non metallic pumps move large volumes efficiently and actively resist corrosion, abrasion and chemical attack. Unlike metal pumps, non-metallic construction eliminates rust, pitting and chemical fatigue.

This directly improves efficiency and life cycle cost. Alfa Pumps engineers its solutions around real industrial loads, not lab assumptions. With optimised hydraulic design, Alfa pumps maintain stable flow even under variable pressure.

These pumps from Alfa are built for continuous duty cycles, where shutdowns are not an option. These are engineered for Indian process conditions: high temperatures, aggressive media and fluctuating utilities. The result is predictable performance, lower maintenance and higher plant availability, where output matters every single hour.

This performance consistency is especially critical in Speciality Chemical manufacturing, where process stability and material compatibility directly impact product quality. Product platforms like the NK Series are designed to deliver stable performance across chemical processing, water treatment and continuous-duty industrial applications.

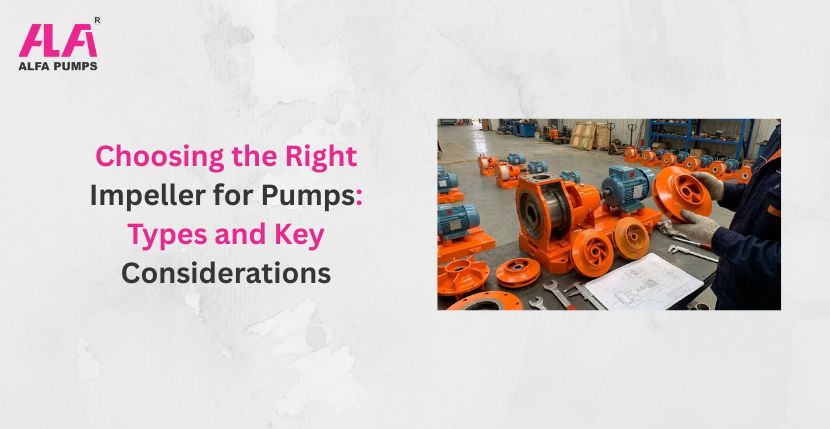

Technical Advantages of Heavy Duty Non-Metallic Pumps:

- Resist corrosion up to 3–5× longer than conventional metal pumps in chemical services

- Non-metallic hydraulics reduce scaling and efficiency drop over time

- Lighter construction lowers energy consumption and foundation costs

- Proven flow stability in high-throughput applications like chemicals, effluent and mining

- Designed and manufactured in India for faster support and lower total ownership cost

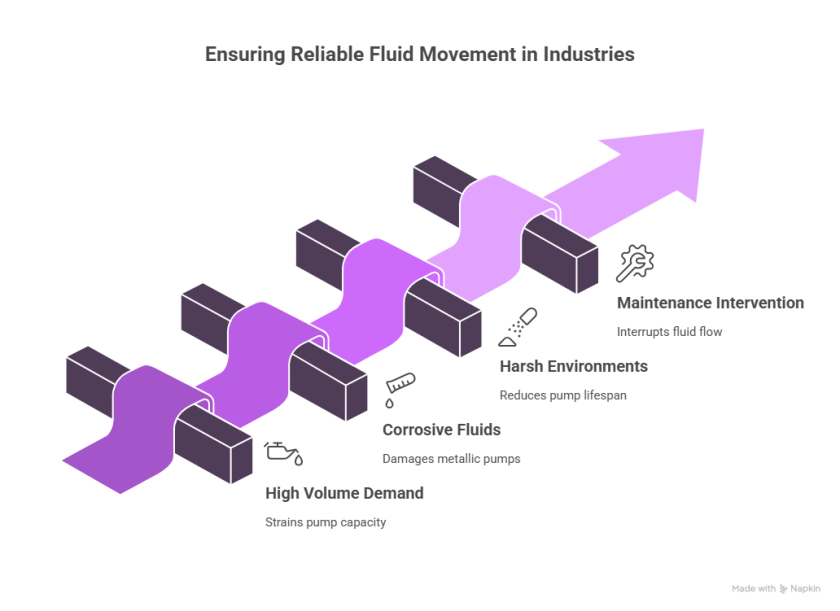

Role of High-Capacity Pumps in Supporting Large-Scale Industrial Operations:

In today’s fast-moving industrial world, reliable fluid movement isn’t a luxury — it’s a backbone of productivity. High capacity industrial pumps quietly drive operations in everything from power plants to wastewater treatment, moving massive volumes of liquid every hour. Globally, the industrial pumps market is worth over US $60 billion, with high-volume systems playing a leading role in oil & gas, mining and energy sectors.

In India, this demand translates into rapid expansion, making Indian made non metallic pumps a practical choice for corrosive fluids and long-life service in harsh environments. Heavy duty non metallic pumps help industries avoid breakdowns and boost uptime, especially where metal alternatives fail.

In high-volume effluent handling and corrosive service lines, solutions such as the TNP Series help maintain uninterrupted flow with reduced maintenance intervention.

Application-Specific Performance Across Process Industries:

High capacity non metallic pumps from Alfa are engineered for specific industrial applications, not generic usage. In chemical plants, they handle acids, alkalis and solvents safely without corrosion risk. In mining operations, they perform reliably in slurry transfer, tailings management and process water circulation. Water and wastewater treatment plants use these pumps for effluent handling, chemical dosing and recycling systems.

In pulp and paper industries, they support continuous flow of chemically treated liquids. Power plants and energy sectors benefit from their ability to handle cooling water and chemically contaminated fluids. This application-focused design ensures optimal performance across diverse industries.

Case Study: Alfa Pumps Installation at Hindustan Zinc

At Hindustan Zinc, water is mission-critical. The company recycles over 71 billion liters of industrial water to cut freshwater use and support its massive mining operations in Rajasthan. To keep that system running smoothly, Hindustan Zinc partnered with Alfa Pumps to install a 1000 cubic meter high capacity non metallic pump engineered for heavy industrial service. Alfa’s pumps are built to handle corrosive and abrasive fluids with precision and reliability, a must for mining process water.

This installation transformed how water moves through the plant’s treatment and recycling loop. Instead of multiple smaller units that break down often, the high capacity industrial pump cuts downtime and boosts efficiency. This is, especially in corrosive environments where metal pumps falter. Such pumps now ensure continuous workflow, lower maintenance costs and better sustainability outcomes at one of India’s largest mines. The result? More uptime, more savings and smoother operations day after day.

Compliance with Global Standards and Quality Testing:

Alfa Pumps designs and manufactures high capacity non metallic pumps that align with international quality and performance standards. Each pump undergoes strict testing to ensure pressure stability, flow accuracy and structural integrity under load. Material compatibility is verified to suit aggressive chemicals and abrasive fluids. Precision manufacturing ensures tight tolerances, leak prevention and long-term reliability. This commitment to quality allows Alfa Pumps to deliver Indian made non metallic pumps that meet global industrial expectations.

Technical Features of Non-Metallic Pumps That Support Industrial Applications:

- Corrosion-resistant thermoplastics and composites suited for aggressive chemicals

- Lightweight construction without compromising structural rigidity

- Smooth compatibility with high capacity industrial pumps operations

- Precision-moulded components ensuring tight tolerances and leak prevention

- Excellent resistance to abrasion, scaling and chemical crystallisation

- Thermal stability for fluctuating process temperatures

- Low vibration design reducing stress on pipelines and foundations

- Energy-efficient hydraulics supporting continuous-duty cycles

- Minimal maintenance needs compared to metallic alternatives

- Long service life even in corrosive and slurry-handling applications

- Engineered robustness matching international standards

- Optimised flow paths enabling Alfa pumps to operate smoothly under load

These corrosion-resistant characteristics make high capacity non metallic pumps particularly suitable for Chlor Alkali plants handling highly aggressive chemicals under continuous load.

Sustainability Impact Beyond Compliance:

Sustainability is not just a requirement, it is a responsibility. High capacity non metallic pumps support sustainable industrial operations by enabling higher water recycling, reduced chemical leakage and lower energy consumption. Their longer service life reduces material waste and replacement frequency. Lightweight construction also lowers transportation-related carbon impact. By supporting efficient fluid movement with minimal losses, Alfa Pumps contributes to reduced environmental footprint while maintaining high productivity.

Industries Where Indian-Made High-Capacity Non-Metallic Pumps Have the Greatest Impact

Across India’s most demanding industrial environments, reliability is a matter of survival. From corrosive chemicals to abrasive slurries and nonstop operations, industries today need pumping solutions that don’t fail under pressure. This is where Indian made non metallic pumps from Alfa Pumps are creating real, measurable impact. Designed for endurance, they are redefining performance in mining, chemical processing, pulp and paper, wastewater treatment and energy sectors. All because they have corrosion resistance, lower maintenance needs and ability to handle all kings of aggressive fluids. These are the smarter, long-term choice for plants focused on uptime, safety and cost efficiency.

Read Also: Non-Metallic Pumps for Corrosive Chemicals A Buyer’s Guide

Emerging Trends in Indian Non-Metallic Pump Technology:

The Indian pump market is shifting fast in 2025. Pump makers like Alfa Pumps are tapping high capacity non metallic pumps to meet rising demand across water, agriculture and smart city projects. IoT-enabled systems and remote monitoring are now part of modern designs, helping cut downtime and boost uptime.

There’s a clear push toward Indian made non metallic pumps that suit harsh chemicals as well as the wastewater environments. Meanwhile, sustainability and energy-efficient solutions are becoming table stakes for competition, forcing heavy investment in innovation and automation.

Why Be Out of the Race to Excel?

In industries where downtime burns money every minute, choosing the wrong pump is a silent risk. Aging metal systems corrode faster, fail under pressure and inflate maintenance costs by up to 30–40% annually. That’s why pumps built with advanced polymers are now replacing legacy equipment worldwide. Our Heavy duty non metallic pumps are engineered to handle extreme flow, aggressive chemicals and continuous loads. That too without rust, scaling or sudden breakdowns. We meet global standards at a lower lifecycle cost. Delay today and competitors will outrun you tomorrow. Act before inefficiency becomes irreversible. Connect with us today.

FAQs:

Non-metallic high-capacity pumps are designed to handle corrosive chemicals, abrasive fluids and continuous operations common in Indian industries. High capacity corrosion-resistant industrial pumps from India perform well even under fluctuating power and harsh site conditions.

Non-metallic pumps do not rust, pit or react with aggressive chemicals, unlike metal pumps. This makes chemical-resistant high flow pumps manufactured in India more reliable and cost-effective for long-term chemical handling.

Yes, these pumps are specially engineered for 24/7 operations without frequent breakdowns. Heavy duty non-metallic pumps for continuous industrial processes ensure stable flow and reduced downtime.

Industries like chemicals, mining, water treatment, pulp and paper, and power plants benefit the most. Large flow non-metallic pumps for corrosive and abrasive fluids are ideal where metal pumps fail frequently.

They are made from advanced thermoplastics and composites tested for chemical compatibility. Acid and alkali handling non-metallic pumps with high flow rate offer safer and longer operation.

Mr. Sanket Patel is a visionary industrial leader and managing director of Alfa Pumps. He leads the company’s innovation in fluid handling solutions, focusing on chemical process pumps designed for corrosive fluids.